We place a premium on safety and health.

-

Safety and Health PolicyHousing & Building Business DivisionDL E&C Housing & Building Business Division declares the safety and health of everyone working together as an absolute value that cannot compromise with anything else, and implements the following health and safety policies for creating “A workplace where safety measures must be implemented.”Safety and Health Policy

- We create a safety culture that always does what we set out to do

- We designate and check strong objects (vehicles), heavy objects (heavy lifting), and high places (working at height) as high-risk spots.

- Safety and health management does not stop at 99%, but finds and removes the last 1% of risk factors.

- We recognize risks and thoroughly implement preventive actions through the high-risk spot system.

- We strictly comply with safety and health procedures and regulations and put top priority on worker protection.

- We guide the voluntary participation of workers in safety and health activities through risk assessment for all work processes.

We bring this policy to the attention of our employees, supply chain partners, and relevant interested parties, and establish Safety and Health objectives and periodic reviews to constantly strengthen its Safety and Health management.Housing & Building Business Division CSO Ma, Changmin -

Safety and Health PolicyCivil Business DivisionCivil Business Division clarifies that the health and safety of employees and everyone else is an absolute value that cannot compromise with anything else and implement the following health and safety policies for creating "an Accident-free Workplace".Safety and Health Policy

- We recognize that health and safety is an absolute priority for sustainable development.

- We do not execute unscheduled work.

- We do not proceed with work under any circumstance unless safety is ensured.

- We recognize risk in advance and establish safety measures at every single stage.

- We ensure a healthy and safe workplace and maintain it all the time.

- We get workers involved in the health & safety activities and encourage them to conduct safety initiatives.

- Management consistently shows commitment to health and safety and provides resources needed.

We will bring this policy to the attention of our employees, supply chain partners and relevant interested parties; and set the safety and health goals and promote them, and through the periodic reviews, safety & health management system should be continuously improved.Civil Business Division CSO Kwon, Sooyoung -

Safety and Health PolicyPlant Business DivisionPlant Business Division clarifies that the health and safety of employees and everyone else is an absolute value that cannot compromise with anything else, and implements the following health and safety policies for creating “An Accident-Free Workplace”Safety and Health Policy

- We understand that health and safety are necessary conditions for long-term growth.

- We essentially prevent accidents by implementing double and triple safety procedures that go beyond safety and health laws.

- We anticipate hazards and implement preventive measures at all levels of the business.

- We ensure a safe and comfortable working environment and keep it in top shape.

- We ensure that workers participate in safety and health activities and encourage them to practice autonomously.

- Headquarters management reiterates its commitment to safety and health and continues to provide the required resources.

We will notify stakeholders about this policy, define and implement safety and health goals, and constantly enhance the safety and health management system through periodic evaluation of implementation status.Director of Plant Business Division (CSO), Yoo Jaeho

ISO 45001 (Safety and Health Management System)

On January 13, 2009, the international standard safety and health management system 'OHSAS 18001' was initially approved, and on November 8, 2018, it was changed to ISO 45001. Based on this certificate,

DL E&C has been verified by a third party by identifying all risk factors involved in business activities in advance and evaluating the risks.

To maximize our safety and health management system, we are constantly enhancing it.

- Scope of certification : All operating divisions

- Scope of certification : All operating divisions

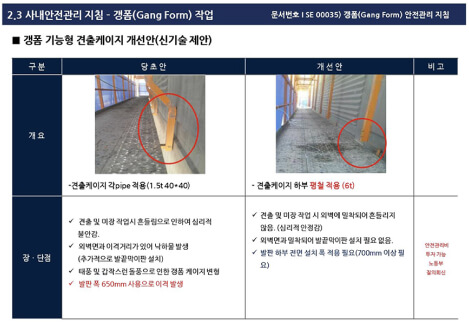

Intensive Management Policy

Every year, DL E&C chooses policies to be controlled actively by examining the sorts of accidents and improvement needs.

The chosen policy is implemented throughout all business divisions and serves as a driving factor in the pursuit of zero accidents.

Recognizing the health and safety of everyone including our employees as our top priority,

we put health and safety first and are implementing our health and safety policy to create a work environment free of accidents. (Target: zero fatal accidents, including contractors)

Creating a workplace where accidents do not occur

What is Risk Assessment (SORA)?

This is a preventative activity that identifies, distinguishes, and evaluates potential risk factors based on work progress conditions for each process to eliminate or limit risk factors.

* SORA : Safety Operation Module & Risk Assessment

Work Flow Chart

- Set work unit once every 2 weeks

- Objectively identify situations by work unit and assess risk factors

- Determine risk level

- Set tolerance scope

- Establish risk management improvement plan

- Conduct training / make work decisions

- Implement status check

Safety Experience School

Experiencing the risk factors associated with each type of disaster and obtaining vital knowledge for safety and accident prevention actions

We are performing experiential education by assembling 21 different contents to enhance the ability to see danger (cognitive ability)

by directly experiencing risk factors and unsafe conditions that may arise in the field, as well as to improve awareness of the accident process,

the establishment of safety measures, and emergency response capabilities.

The Safety Experience School provides safety training for not only our employees but also those of public institution and suppliers.

As of the end of 2021, a total of 2,844 people (2,609 in 2019, 212 in 2020, 23 in 2021) have participated in training to acquire experience and safety knowledge.

While ESG management initiatives (Social = social responsibility) are ongoing, we are expanding education for the general public to contribute to the local community.

We provide free community safety education to local people, students, and local government offices in order to avoid and respond to the dangers of safety accidents not only on building sites but also in everyday life.

Implementing a total of 21 safety experience programs

The Exterior of Safety Experience School

VR Experience of Temporary Passage

Equipment Experience

Falling Experience from Opening

Scaffolding Practice

Emergency Measure Experience

ISO 21001 (Educational Institution Management System)

On January 16, 2020, we increased the dependability of safety experience school education and obtained ISO 21001, which is recognized both domestically and globally, for the first time as a global learning service provider.

Safety Experience School Certificate

For the first time in the construction business, we received the 'Certificate of Private Safety Experience Training Center' from the Korea Occupational Safety and Health Agency on June 21, 2021.

Safety Inspection Led by Management

CSO sets an example at the forefront as he conducts

on-site inspections once a month. In order to raise the level of responsibility of executives, the number of safety inspections and serious accidents were reflected in the executive KPI.

Approval of BOD (Board Of Directors) Reports About Safety and Health

In accordance with the Occupational Health and Safety Act, the health and safety plans, and their progress are reported to the board of directors for approval on an annual and quarterly basis respectively.

BOD (Board of Directors) approval status related to safety and health

| Year | Date of Meeting (No. of Session) |

Agenda | Approval Status |

|---|---|---|---|

| 2022 | 2022.02.22 (Session 2) | Approval of 2022 Safety and Health plan | Approved |

| 2021 | 2021.03.23 (Session 4) | Approval of 2021 Safety and Health plan | Approved |

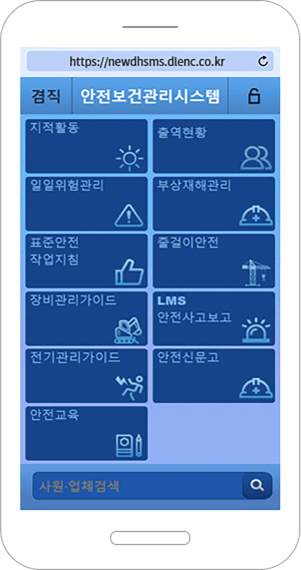

Real-time Safety Management

Real-time risk management using high-risk spot management process

We developed and applied the high-risk spot management process, a "system that directly verifies risk factors," to monitor the status of risk management at all sites in real time at the headquarters, in order to prevent safety accidents in advance by strengthening the governance of on-site high-risk work.

Establishing daily risk management monitoring system

-

Register risk factors

-

Automatically sends risk factors and countermeasuresDL Manager / Supplier Manager / Supplier Work Group Supervisor

-

Conducts on-site inspection

-

Head office confirms

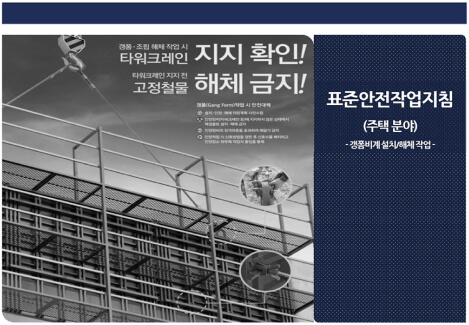

Standard Safety Work Guidelines

We identified 48 jobs and types of work with a high accident frequency based on an analysis of major incidents over the last ten years (our firm and other companies), and linked them with mobile to make them available in the field at any time.

- Anyone can sympathize and easily understand the right safety guidelines

- Directly applying to educational materials, safety management tasks, etc.

- Integrating and standardizing guidelines to unify maintenance and management

Improving efficiency of

safety work

safety work

Examples of standard safety work guidelines

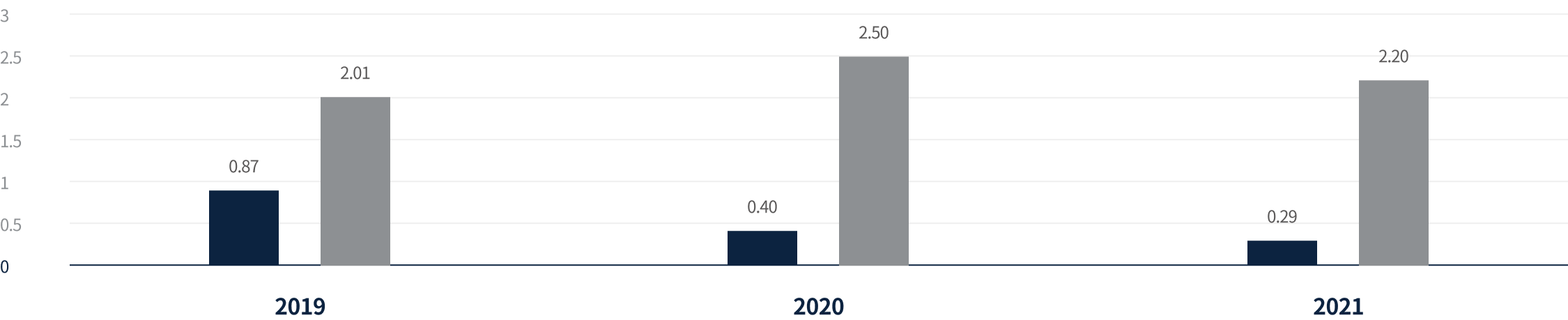

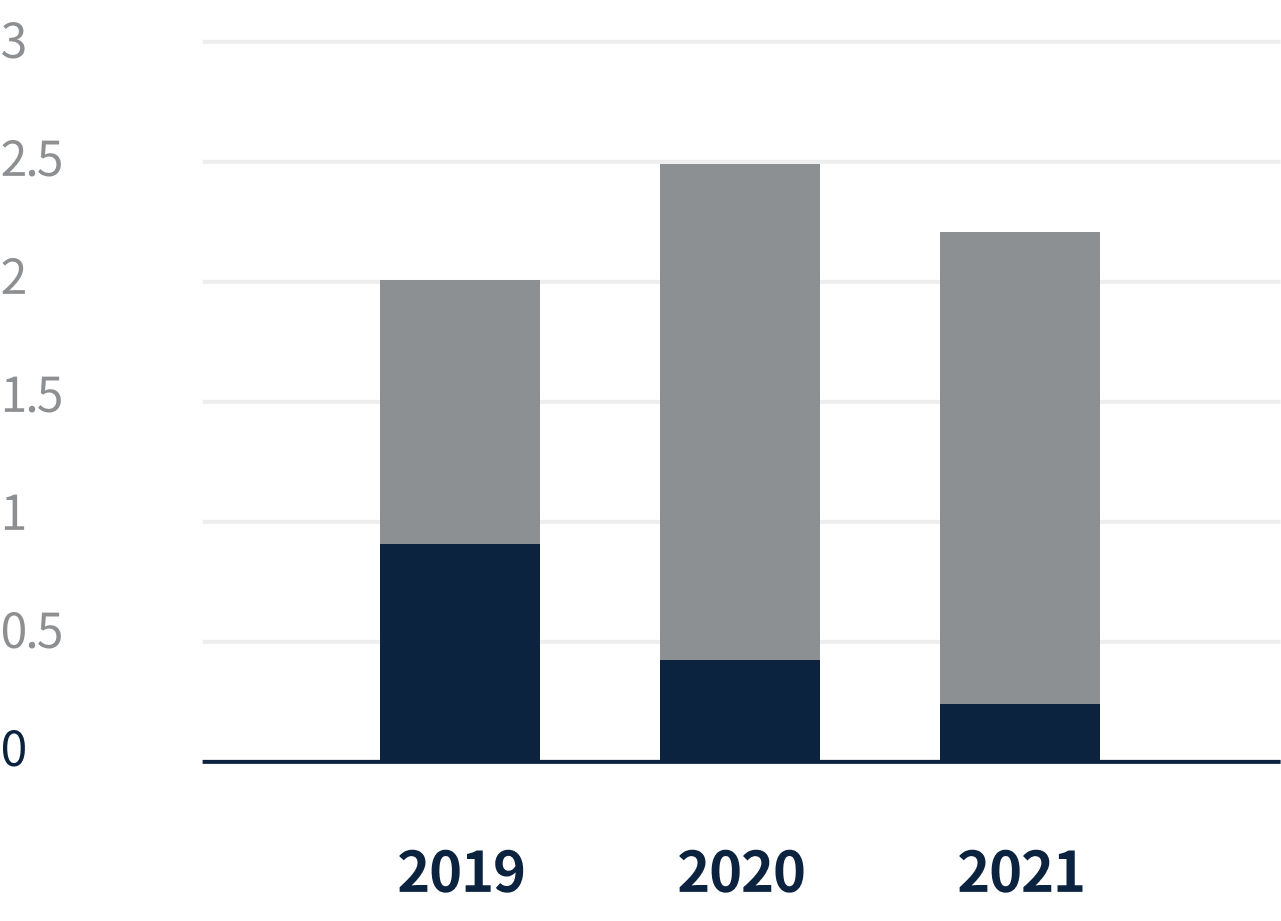

Current status of death rate

Performance

Average of Construction Industry

| Section | 2019 | 2020 | 2021 |

|---|---|---|---|

| Performance | 0.87 | 0.40 | 0.29 |

| Average of Construction Industry | 2.01 | 2.50 | 2.20 |