We provide the greatest degree of quality to our consumers.

DL E&C sets and implements the following policy in order to become a global first-class organization by offering our customers with high-quality products and services.

Quality Policy

- Providing customer happiness based on the fundamentals and principles

- Strengthening the value of corporation by assuring the greatest technologies

- Improving quality compatibility through continual process innovation

- Increasing the effectiveness of preventative measures through systematic risk management

- Providing the highest quality possible through collaborative growth management with subcontractors

To achieve this quality policy, we establish and implement quality targets for each unit, as well as monitor implementation progress to continuously enhance the quality management system. We will do everything possible to provide the highest quality that will impress our consumers.

CEO Changmin Ma

ISO 9001

ISO 9001 is an international standard for a quality management system developed by the International Organization for Standardization. It has been maintained by DL E&C since its first acquisition in 1994.

-

ISO 9001: 2015

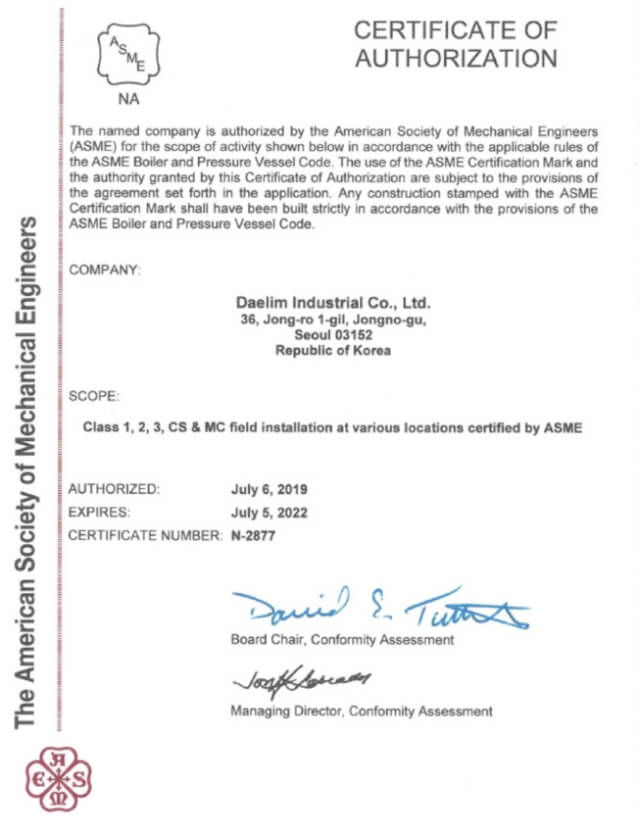

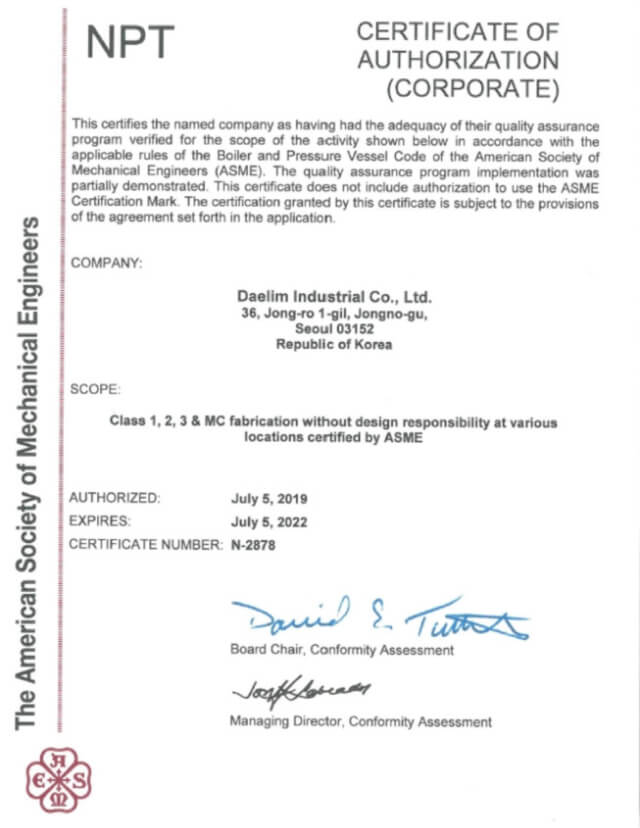

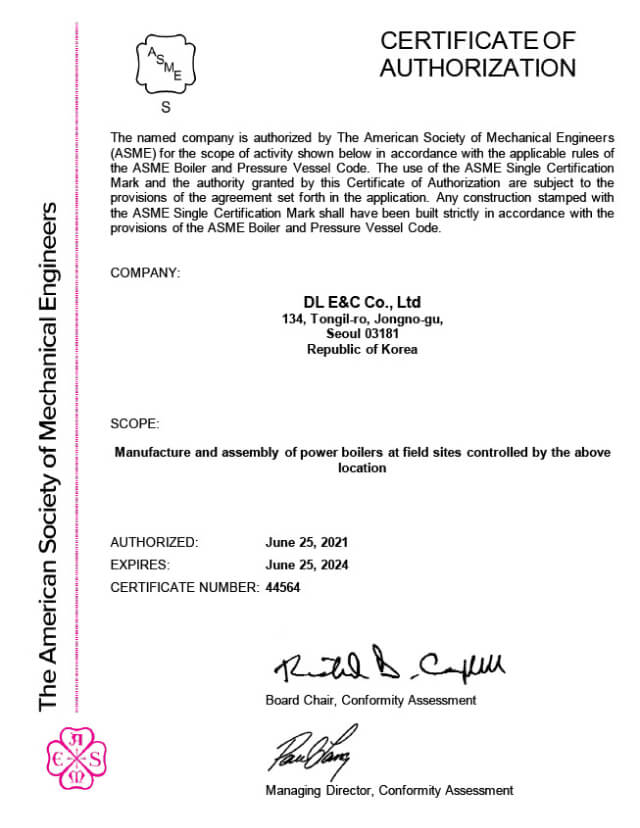

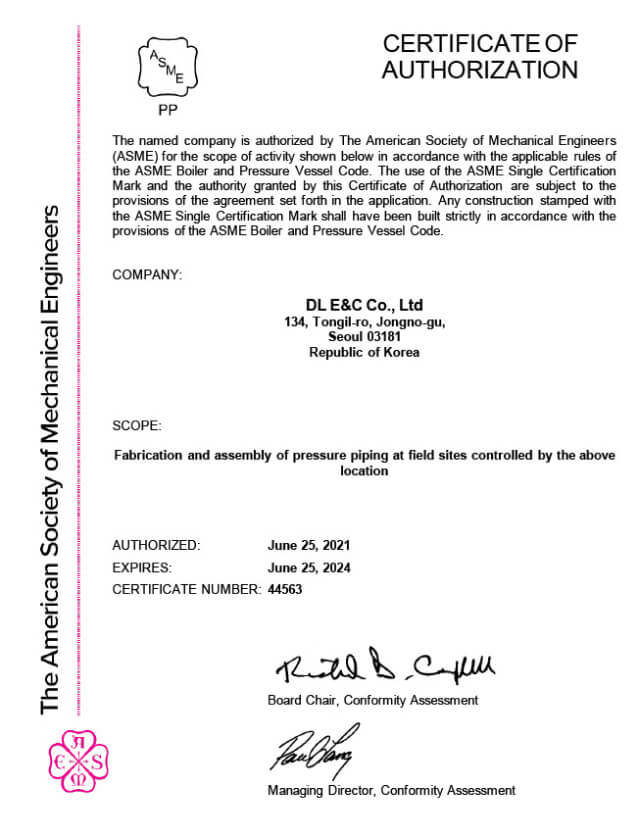

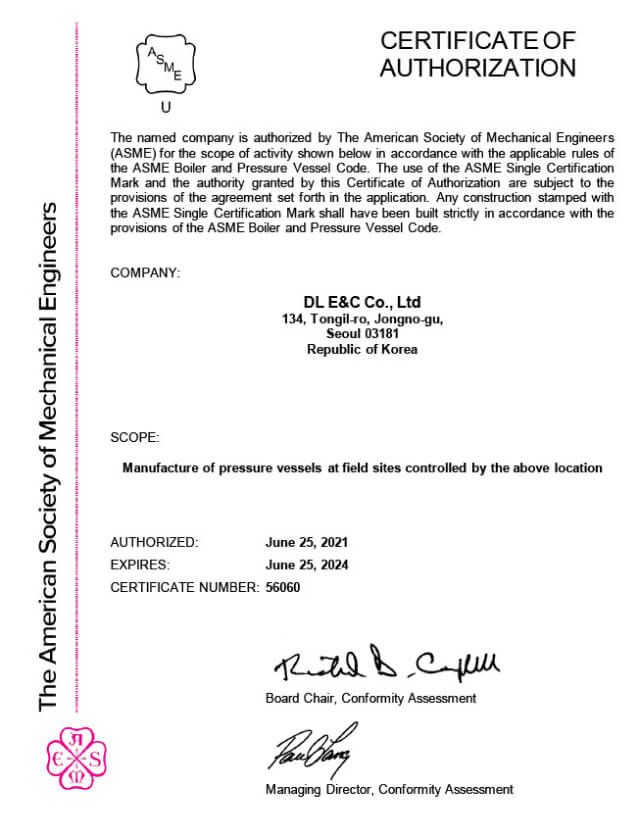

ASME (Non-Nuclear Power)

ASME is the American Society of Mechanical Engineers' technical standard for the manufacturing and installation of pressure vessels (U), boilers (S), and pressure piping (PP). It adds to the objective dependability of DL E&C's quality assurance system and quality management.

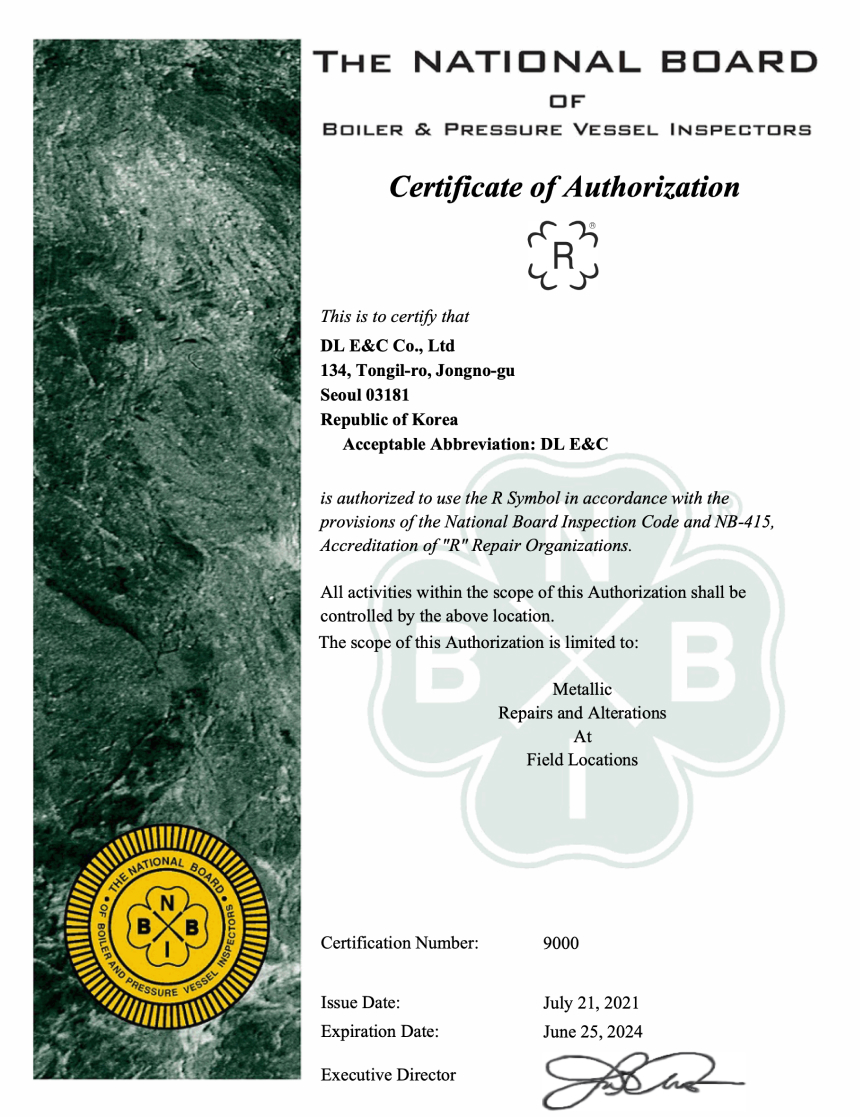

NBBI

It is a certificate provided by the US NBBI (National Board of Boiler and Pressure Vessel Inspectors) for quality assurance efforts on boiler and pressure vessel performance.

-

R (Repairs and Alterations)

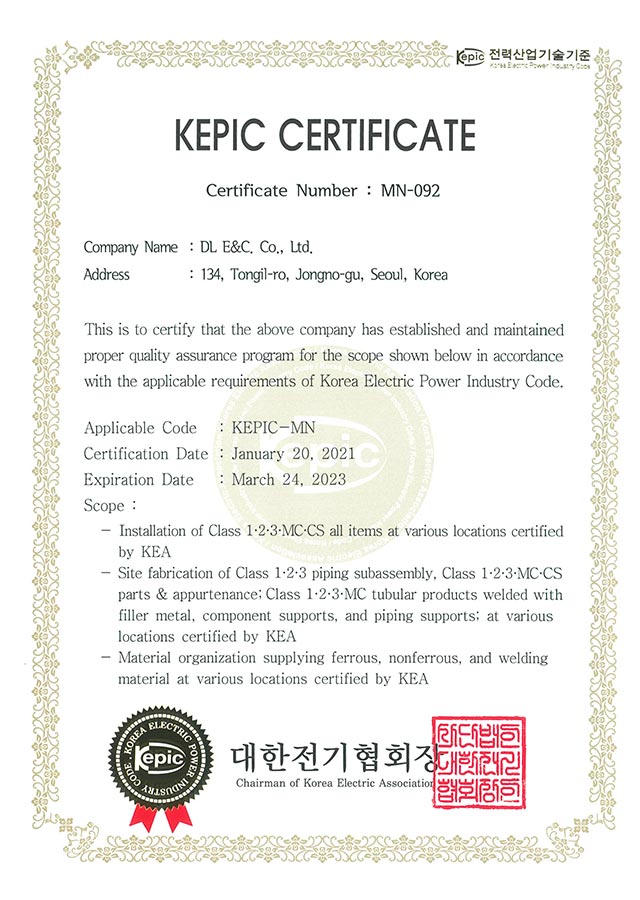

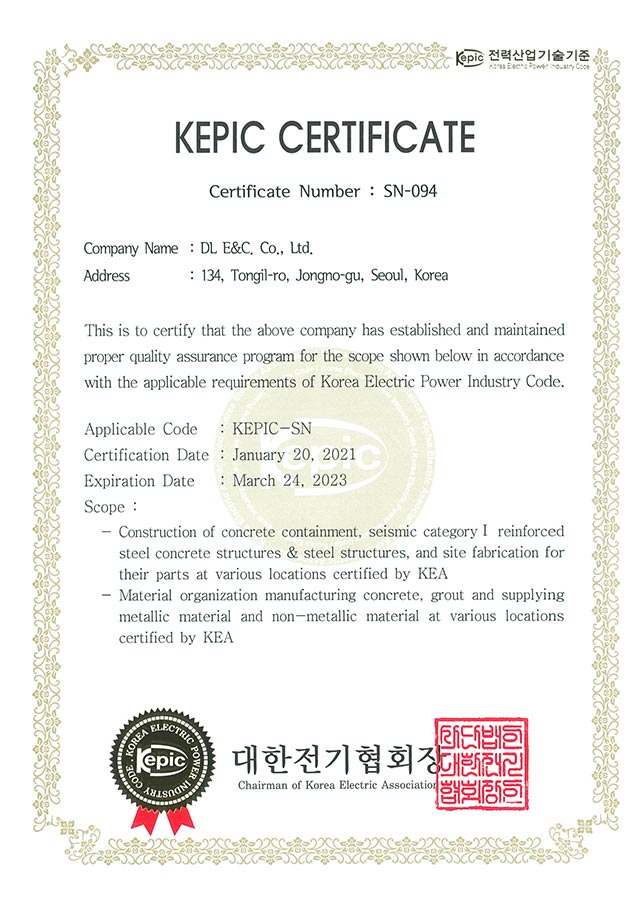

KEPIC

It is a qualification certificate granted from the Korea Electric Association for having the capabilities to manage and apply the nuclear quality assurance program in compliance with KEPIC as a nuclear power facility installation and construction company.

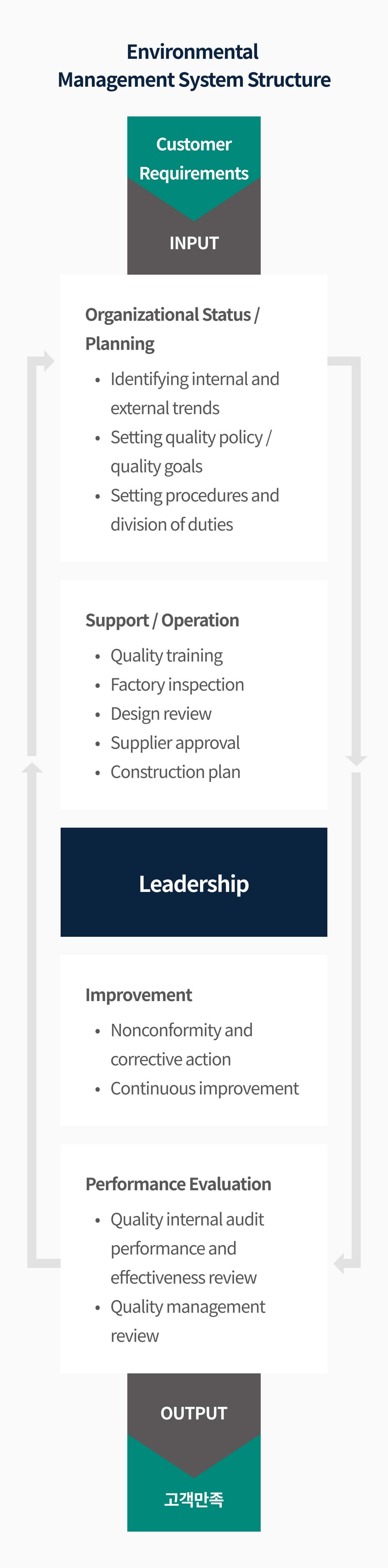

ISO 9001 Implementation

We design and operate the quality management systems at the headquarters and construction sites in accordance with ISO 9001 standards to ensure customer satisfaction and performance improvement.

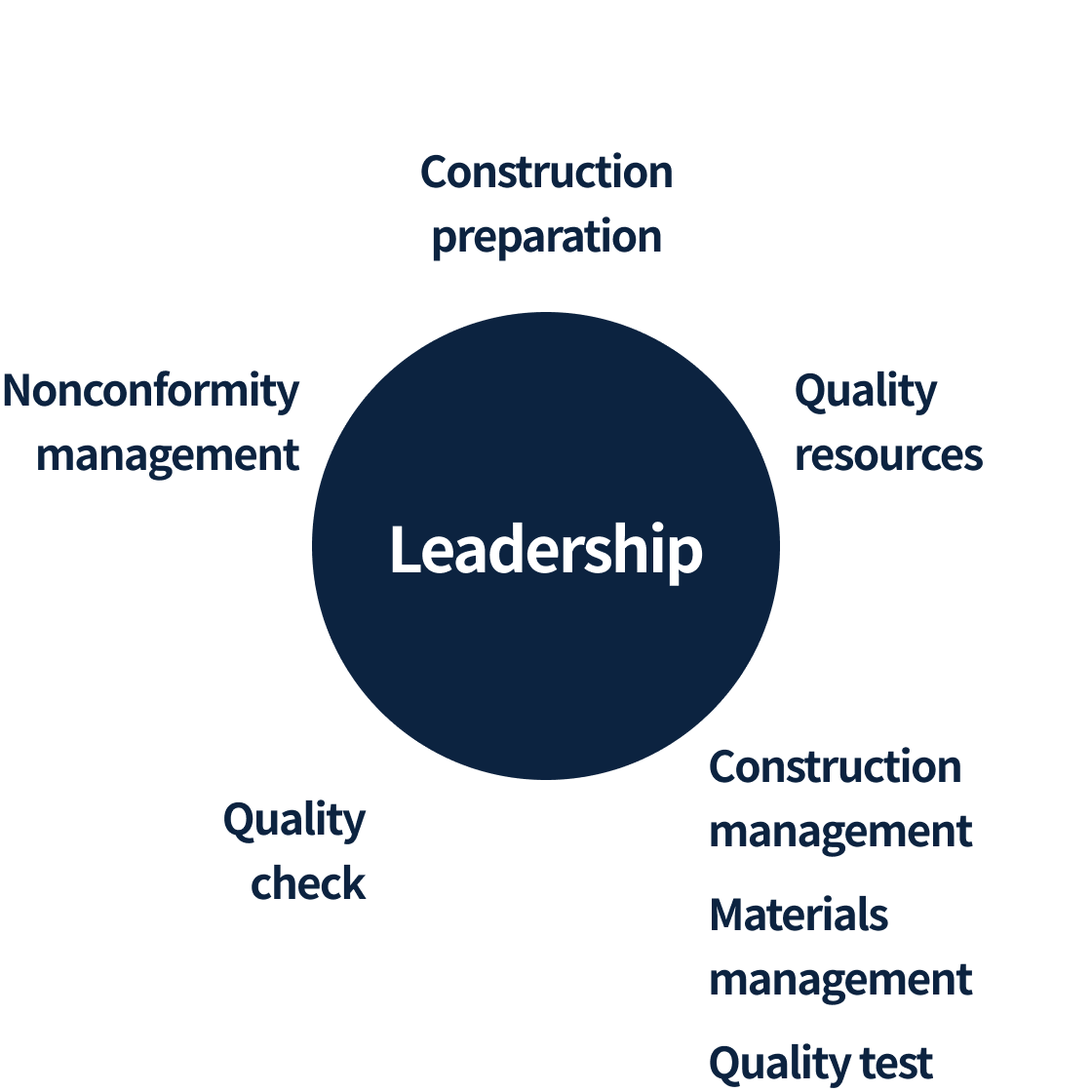

Operating DL E&C Quality management system (DQMS)

DL E&C Quality Management System is a system that efficiently supports and administers on-site quality activities to achieve legal standards and prevent faults in the future.

Quality resources

- Quality manager information

- Test / Inspection equipment

- Quality manager training

Construction preparation

- Quality policy

- Quality objectives

- Responsibilities and authority

Construction management Materials management Quality test

- Design review

- Construction plan

- Quality Test and Inspection

Quality check

- Inspection of product quality

- Inspection of infrastructure management status

Nonconformity management

- Nonconformity reports

- Corrective action reports

Main Activities of DQMS

- Establishment of advance plans for each process and management of performance

- Dissemination of best practices for quality control by item

- Issuance of non-conformity reports and follow-up actions

Quality Training and Inspection

We provide tailored training for each class in order to meet legal requirements and increase the competency of quality manpower.

-

On-site quality manager job training

On-site quality manager job training -

Supplier manager and supervisor training

Supplier manager and supervisor training -

Quality manager test practice training

Quality manager test practice training -

Headquarters’ quality manager training

Headquarters’ quality manager training -

Life cycle field monitoring

Life cycle field monitoring

Quality Audit

Conducting quality inspection on-site

Site

(by Business Division SEQ RM Team)

Headquarters

(SEQ RM Team)

Executing internal audit of quality control system

Supporting on-site quality by stage

-

Supporting to secure design quality

- BIE-based design optimization

- IDC (Third-party design verification)

-

Supporting initial set-up for new sites

- Support for preparing legal quality documents

- Support for providing test rooms and test equipment

- Allocating quality managers

- Quality KOM (Kick off meeting)

-

Supporting Quality diagnosis and operations

- Quality inspection by each step

- Zero defect inspection

- Quality control plan adequacy inspection

- Penalty prevention diagnosis

-

Supporting quality on completion sites

- Adequacy review of completion documents

- Construction quality inspection

Customer Satisfaction Activities

-

[Under construction] In-house quality inspectionIn order to improve the satisfaction of tenant customers, we are conducting a self-quality inspection (D-90) from the user's perspective, with the goal “Zero Defect” before the tenant's pre-visit event.

[Under construction] In-house quality inspectionIn order to improve the satisfaction of tenant customers, we are conducting a self-quality inspection (D-90) from the user's perspective, with the goal “Zero Defect” before the tenant's pre-visit event. -

[Before Move-in] Pre-visit event for tenantsWe are holding a pre-visit event for tenants 45 days before the completion of construction, and we have established a mobile defect management solution So that customers check for defects more easily”. Furthermore, by using an expedited handling crew, we provide a service that resolves issues that must be addressed on the day of the event.

[Before Move-in] Pre-visit event for tenantsWe are holding a pre-visit event for tenants 45 days before the completion of construction, and we have established a mobile defect management solution So that customers check for defects more easily”. Furthermore, by using an expedited handling crew, we provide a service that resolves issues that must be addressed on the day of the event. -

Visiting the completed site again to hear the voices of customers.DL E&C_ Godeok Arteon

Visiting the completed site again to hear the voices of customers.DL E&C_ Godeok Arteon -

We commend Acro Riverheim CS Center.DL E&C_Quality Innovation Campaign

We commend Acro Riverheim CS Center.DL E&C_Quality Innovation Campaign